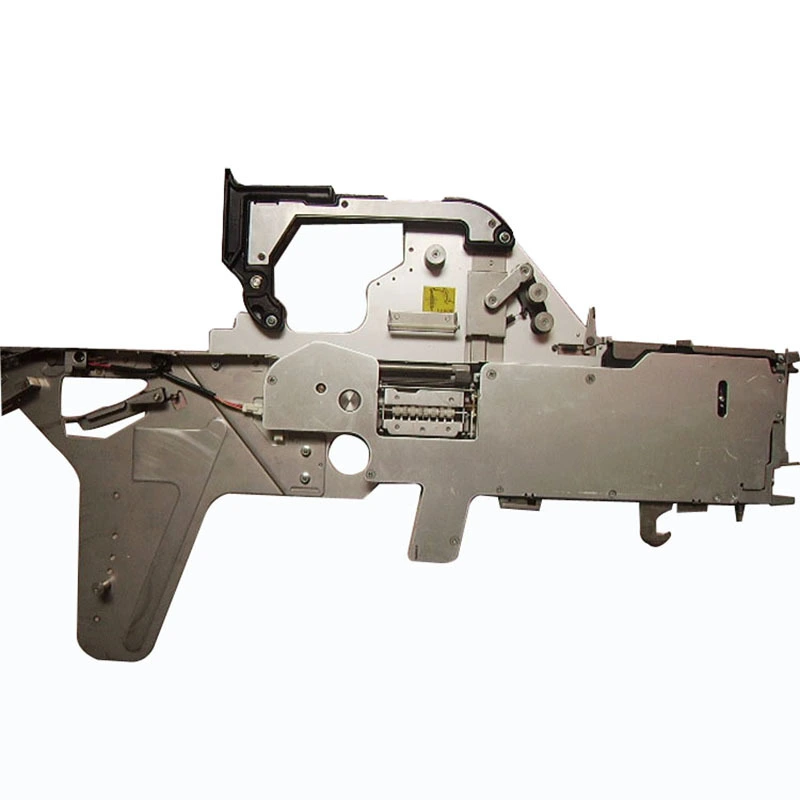

Panasonic BM/MSF8-56MM SMT Feeder: High-Speed Durable Auto Feeder for PCB Assembly

The Panasonic BM/MSF8-56MM SMT Feeder is designed for high-speed PCB assembly, offering reliable and consistent feeding performance. This durable auto feeder ensures smooth operation and enhances production efficiency.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Introduction

The Panasonic BM/MSF8-56MM Electric Feeder is an automated feeding solution specifically designed for high-precision SMT (Surface Mount Technology) production lines. Utilizing Panasonic's leading mechatronics technology, it ensures stable and efficient component conveying, and is suitable for precision PCB assembly scenarios such as smartphones, automotive electronics, medical devices, and so on..

Product Display

BM电动飞达 (1)

BM MSF (1)

0 (18)

0 (19)

微信图片_20241224214458

微信图片_20241224214449

微信图片_20241224214454

微信图片_20241224214413

微信图片_20241224214540

微信图片_20241224214536

微信图片_20241224214532

微信图片_20241224214514

微信图片_20241224214510

微信图片_20241224214506

微信图片_20250410161817

Product Advantages

Ultra-high-speed Feeding The feeding speed can reach up to 800-1200 CPH (Components Per Hour), and it is compatible with high-speed chip mounters (such as Panasonic NPM and CM series), significantly improving the efficiency of the production line. It supports tape reels with a bandwidth of 8-56mm and is compatible with various SMD components such as resistors, capacitors, and ICs.

Precise and Stable Feeding Equipped with a closed-loop servo control system, the positioning accuracy is ±0.01mm, which avoids component rejection or misalignment and reduces the rejection rate. With an anti-static design (ESD Protection), it ensures the safety of sensitive components.

Industrial-grade Durability The body adopts an aviation-grade aluminum alloy frame, which is impact-resistant and wear-resistant, and can adapt to a 24/7 continuous operation environment. The lifespan of the core components exceeds 500,000 hours in terms of MTBF (Mean Time Between Failures), reducing the maintenance cost by 30%.

Intelligent Compatibility It supports the SMEMA communication protocol and can be seamlessly integrated with mainstream chip mounters and production line control systems. With a quick material replacement design, the tape reel can be switched within 5 seconds, reducing the downtime.

Application Scenario

Consumer electronics

Smartphone motherboards, TWS earphone circuit boards, smartwatch modules

Automotive electronics

ECU control board, vehicle-mounted sensors, charging modules for new energy vehicles

LED display

Mini LED backlight module, outdoor display screen unit

Medical electronics

PCBs for medical imaging equipment, implantable sensors

FAQ

1

What is the typical lifespan of an SMT Feeder? How to extend its service life?

Standard lifespan: The average lifespan of an industrial-grade SMT Feeder is 3 to 5 million cycles. For example, the Yamaha CL series can reach up to 8 million cycles.

2

How to fix communication errors between SMT Feeder and pick-and-place machine?

Confirm that the PIN pins of the Feeder interface are not bent or oxidized. Check whether the Feeder firmware version supports the model of the chip mounter. Restart the control unit of the chip mounter and reload the parameter configuration file of the Feeder.

3

Can third-party SMT Feeders match OEM performance?

Third-party Feeders have an advantage in terms of short-term costs, but there are significant differences. For high-precision and large-batch production, it is preferable to choose the original factory feeders. For trial production or scenarios with low complexity, it is possible to try high-quality third-party brands.

4

How to quickly replace worn parts like feeder gears?

Cut off the power supply and remove the tape.

Use a 3mm hexagonal wrench to remove the gear cover plate (pay attention to the spring tension).

Take out the old gear set and compare the pitch consistency with that of the new gear.

Apply thermal conductive silicone grease and then install the new gear.

Use a calibration jig to test the feeding tension (target value: 2.5N±0.3N).

5

Can you customize SMT Feeders for non-standard tape widths?

YES

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Ready to work with us ?

Find us here:

Useful Links

Products

Contact Us

Contact person: jiaqin luo

Tel / WhatsApp: +86 13926805686

E-mail: aismtsupplier@gmail.com

Add:

Songshan Lake Industrial Building, Dongguan, Guangdong, China zip 523808