Професионална производствена, търговска и агентска компания с 16 години опит в SMT машини

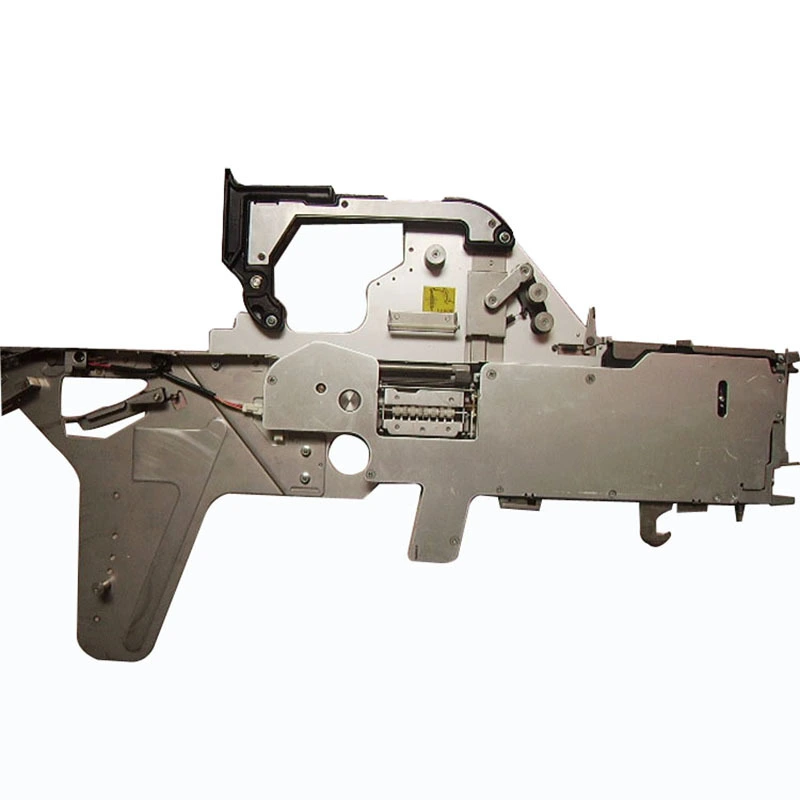

Panasonic BM/MSF8-56MM SMT Feeder: High-Speed Durable Auto Feeder for PCB Assembly

The Panasonic BM/MSF8-56MM SMT Feeder is designed for high-speed PCB assembly, offering reliable and consistent feeding performance. This durable auto feeder ensures smooth operation and enhances production efficiency.

Introducción del producto

The Panasonic BM/MSF8-56MM Electric Feeder is an automated feeding solution specifically designed for high-precision SMT (Surface Mount Technology) production lines. Utilizing Panasonic's leading mechatronics technology, it ensures stable and efficient component conveying, and is suitable for precision PCB assembly scenarios such as smartphones, automotive electronics, medical devices, and so on.

.

Exhibición del producto

Ventajas del producto

Escenario de aplicación

FAQ