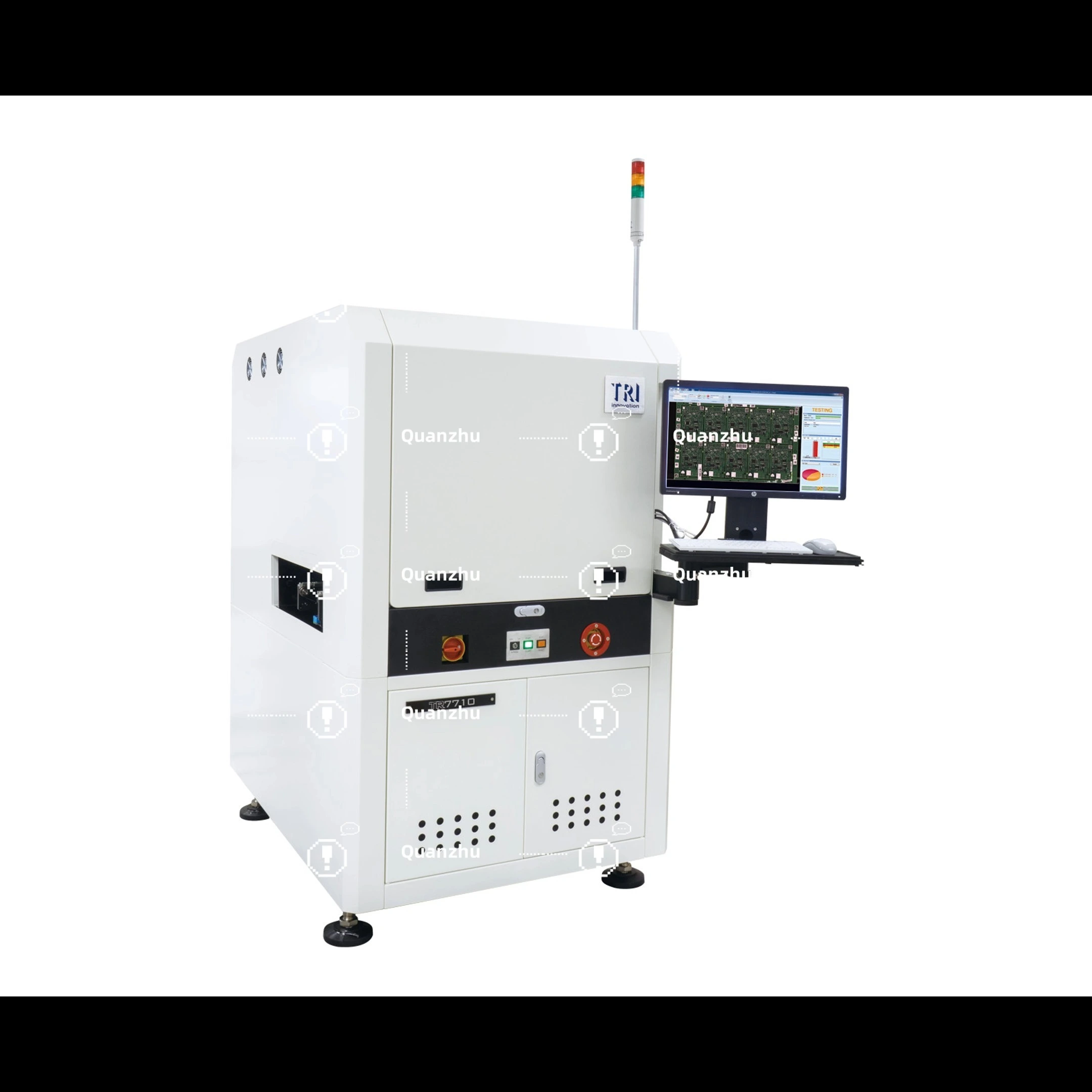

AOI TR7710 Automatic Optical Inspection Machine | High-Speed PCB Inspection by TRI

Fully compatible with Industry 4.0 and MES systems, the TR7710 supports real-time data analysis, defect tracking, and full-line automation. It's an ideal solution for electronics manufacturers seeking accuracy, speed, and long-term reliability in SMT inspection.

Product features:

The TR7710 features a high-resolution multi-camera system and powerful 3D inspection capabilities, allowing it to detect soldering defects, missing or misaligned components, polarity errors, and more. Its advanced lighting system and flexible inspection angles enable thorough coverage of complex PCBs. Integrated with AI-based recognition and low false call rates, it ensures efficient inspection with reduced operator intervention.

Fully compatible with Industry 4.0 and MES systems, the TR7710 supports real-time data analysis, defect tracking, and full-line automation. It's an ideal solution for electronics manufacturers seeking accuracy, speed, and long-term reliability in SMT inspection.

Technical specifications:

-

Inspection Type: Inline 2D/3D Automatic Optical Inspection

-

Camera: High-resolution color camera (up to 25MP)

-

Lighting: Multi-angle RGB lighting + Coaxial + 3D projection

-

3D Capability: Yes – Supports height and volume inspection

-

Detection: Solder bridges, missing/misaligned components, polarity errors, etc.

-

PCB Size: Max. 510mm × 460mm / Min. 50mm × 50mm

-

Component Height: Up to 25mm

-

Resolution: Up to 15µm/pixel

-

Software: TRI AOI Software with AI-enhanced defect detection & SPC tools

-

Integration: MES-ready, Industry 4.0 compatible

-

Interface: User-friendly GUI with review and repair station support

-

Power Supply: AC 100–240V, 50/60Hz

-

Dimensions: Approx. 1000 × 1300 × 1600 mm

-

Weight: Approx. 600–800 kg

Application field:

SMT Production Lines

For inline inspection after reflow to detect solder and placement defects.-

PCB Assembly

Ensures board quality before functional testing or shipment. -

Automotive Electronics

Detects micro-defects in safety-critical and control modules. -

Consumer Electronics

Ideal for high-density boards in phones, TVs, and wearables. -

Medical Devices

Supports traceable, high-accuracy inspection for critical electronics. -

Industrial & IoT Products

Fits smart factories with automated, data-driven inspection needs. -

Telecom Equipment

Verifies complex, high-speed PCBs used in networking systems.

Product Display

Product advantagesFAQ