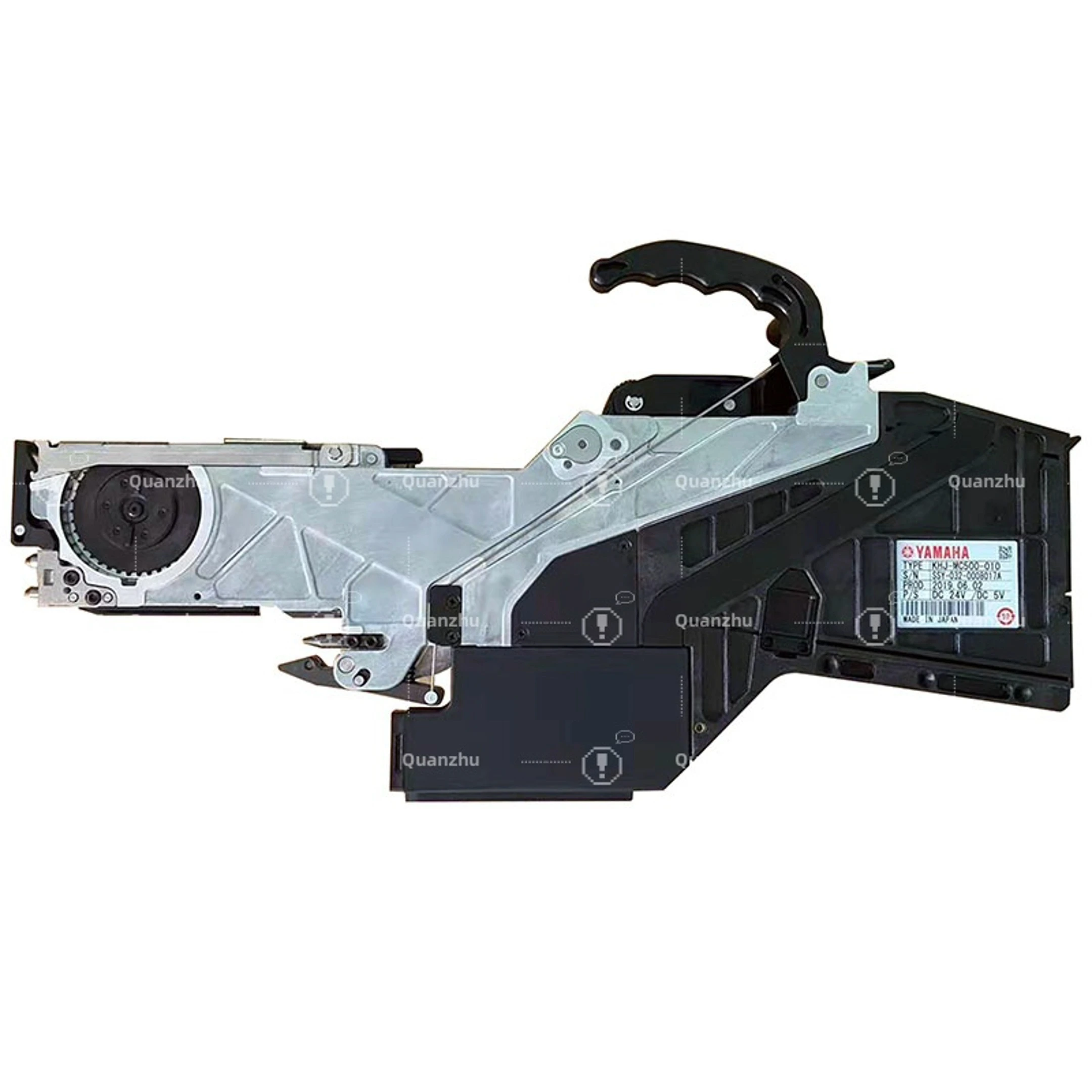

Yamaha Smt Feeder 32mm Khj-Mc500-000 | Original Replacement | Supplier

Core Highlights

| Dimension | Key Content |

|---|---|

| Precise Positioning | Genuine Yamaha SMT feeder (Model KHJ-MC500-000) for 32mm tape components (e.g., QFPs, connectors, modules) |

| Core Function | Stepper motor + optical sensors enable ±0.1mm feeding accuracy and high-speed placement (0.1s/component) |

| Primary Role | Ensures stable component feeding for Yamaha YS/X-series placement machines, minimizing downtime and enabling continuous production |

| Competitive Advantages | ► Miss-feed rate <0.01% (industry avg. 0.03%) ► 304 stainless steel cover + ceramic pawl with >5 million-cycle durability ► ESD protection design (surface resistance 10<sup>6</sup>-10<sup>8</sup>Ω) |

| Decision Value | ★ Cost-saving: Reduces material waste by 20%+ and spare part replacement frequency ★ Efficiency boost: Supports 24/7 operation with placement yield up to 99.95% ★ Full compatibility: Certified for YS12/YS24/YSM20 mainstream models |

Technical Deep Dive

-

Durability Engineering

-

Metal body + ceramic critical parts: Eliminates jamming caused by plastic feeder warping/wear

-

Self-lubricating bearings: Maintenance-free operation >10,000 hours

-

-

Smart Control

-

Dual-channel optical sensors: Real-time tape positioning and component monitoring with auto-correction

-

IP54 rating: Dust/liquid splash protection for harsh workshop environments

-

-

Plug-and-Play

-

Quick-lock pneumatic connector: 3-second installation/swap with hot-swappable support

-

LED status indicator: Red/green alerts for feeding errors (tape-out, jam, misalignment)

-

Product Introduction

The original Yamaha KHJ-MC500-000 SMT feeder is designed for high-speed mounters, offering 32mm standard bandwidth compatibility for all types of rolled electronic components (e.g. ICs, connectors). Adopting high-precision stepping motor and wear-resistant metal structure, it ensures stable material supply and extremely low throw rate, perfectly adapting to Yamaha YS/X series mounters, which significantly improves line efficiency and component placement yield, and it is an ideal solution for high-reliability production in electronic manufacturing.

Product Display

Product Advantages

Application Scenario

FAQ