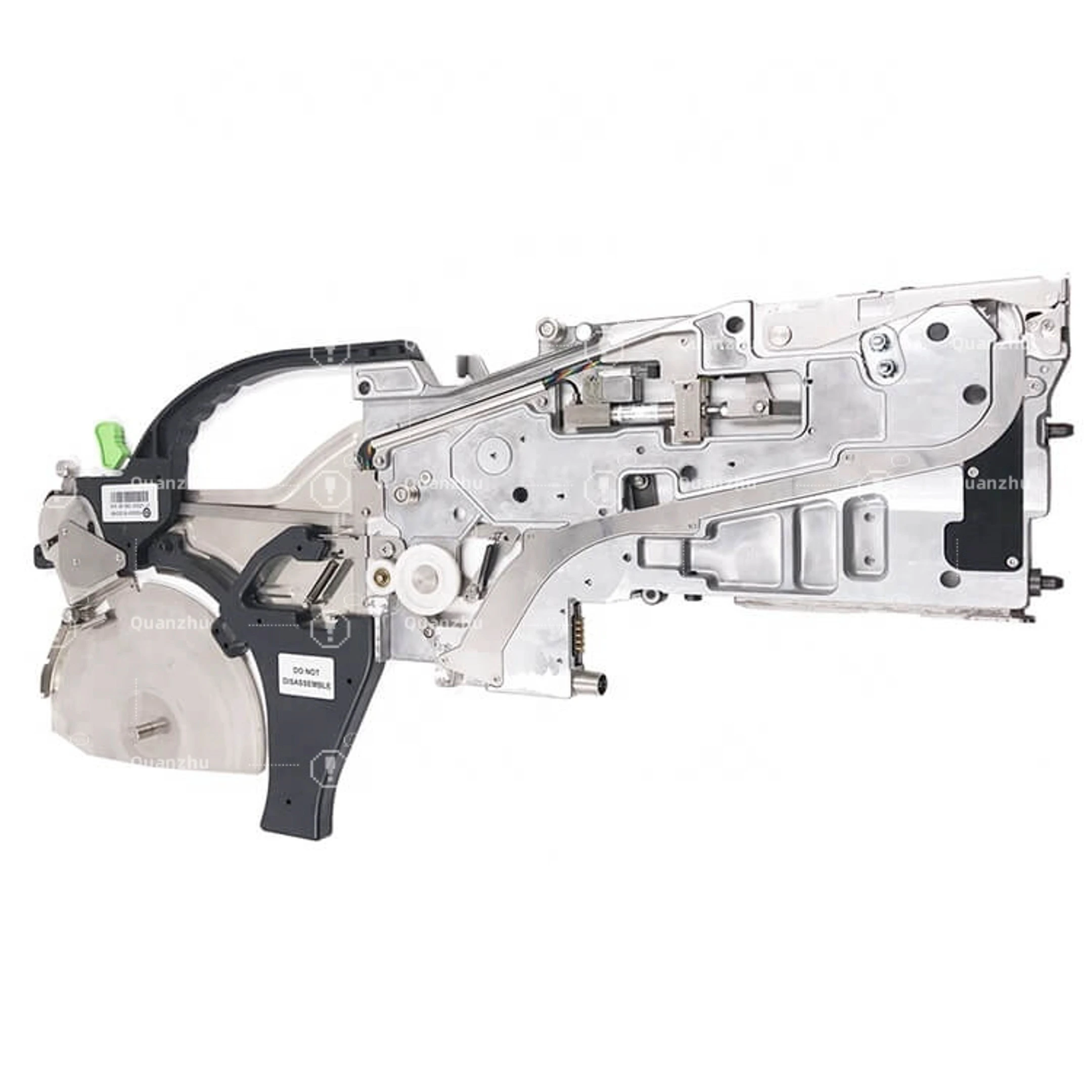

Samsung SMT Feeder 8mm 2mm Pitch – IT Series for High-Speed Micro Component Placement

The Samsung SMT IT Series 8×2mm Feeder is a specialized component feeding unit engineered to meet the demanding requirements of ultra-fine pitch SMD placement. It is tailored for use with 8mm-wide carrier tapes that feature a 2mm component pitch—commonly used for ultra-small components such as 01005 and 0201 chip resistors and capacitors.

Optimized for Samsung CP series pick-and-place machines (including CP40, CP45, CP50, and CP60), this feeder provides unmatched precision and reliability in high-speed SMT assembly environments. Its finely calibrated mechanical drive system ensures accurate tape indexing, precise component alignment, and smooth, consistent feeding throughout long production runs.

Constructed from high-durability aluminum alloys and wear-resistant polymers, the IT 8×2mm feeder withstands continuous operation and minimizes maintenance downtime. It supports both paper and embossed tape formats, allowing for greater flexibility across various packaging types.

The plug-and-play modular design ensures easy installation and quick swap-outs, reducing line downtime and enhancing production efficiency, especially in high-mix, low-volume manufacturing settings. With its stable performance and compatibility, it is a preferred choice for manufacturers focused on microminiature electronic assemblies where accuracy is critical.

(Application Industries)

-

Consumer electronics – smartphones, tablets, wearables

-

Medical devices – compact sensors, microchips

-

Automotive electronics – precision control modules

-

Telecommunication equipment – high-density circuit boards

Product Introduction

The Samsung SMT IT Series 8×2mm Feeder is a high-precision tape feeder specifically designed for ultra-small SMD components packaged in 8mm-wide tapes with a 2mm pitch. Ideal for handling components such as 01005 or 0201 chips, this feeder is optimized for high-speed, high-accuracy pick-and-place operations using Samsung CP series machines, including CP40, CP45, and CP60.

Product Display

Product Advantages

Application Scenario

FAQ