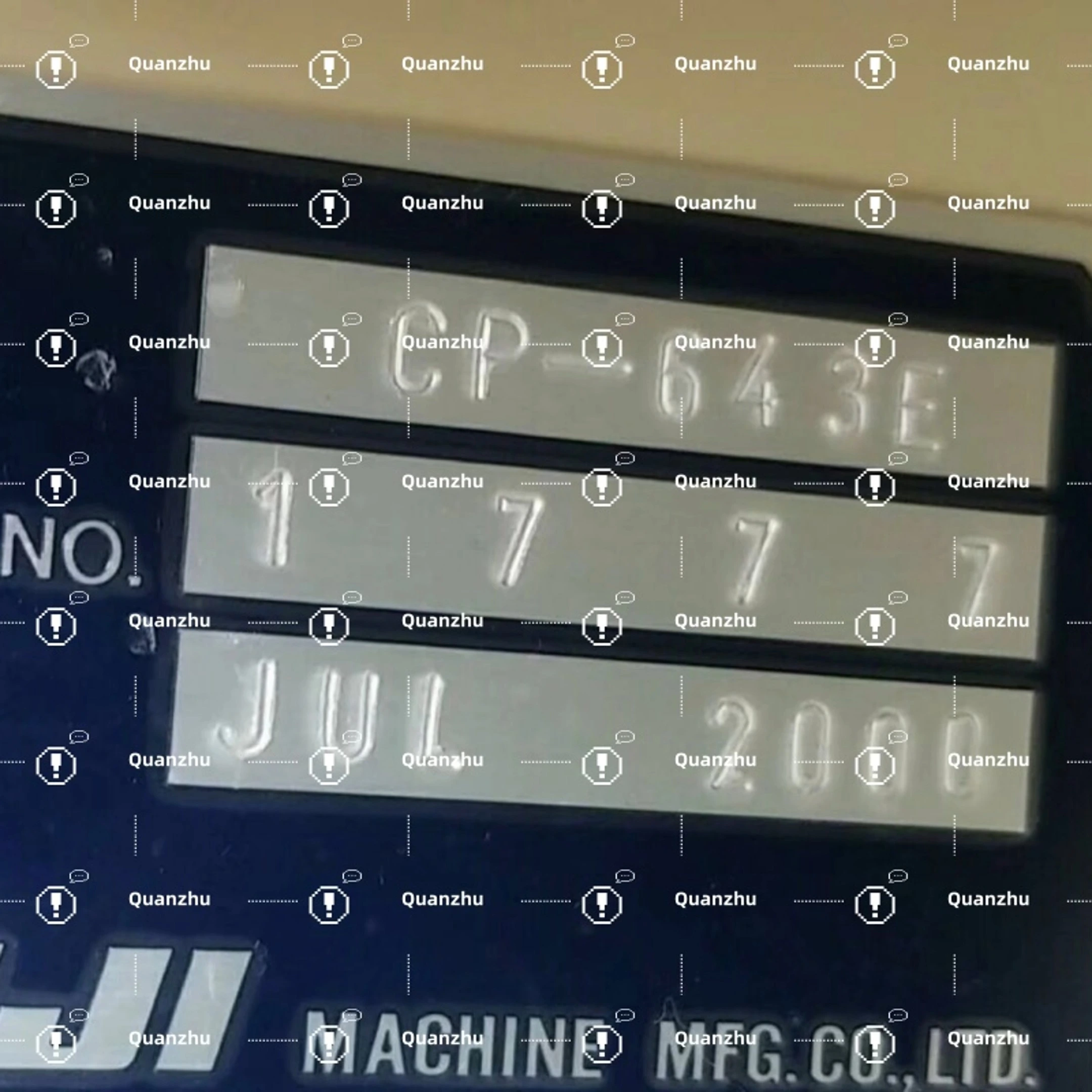

FUJI CP-643E SMT Pick and Place Machine, High-Speed and Reliable Chip Mounter for Precision SMD and PCB Assembly Line

High-speed FUJI CP-643E SMT chip mounter with 40,000CPH and ±0.01mm accuracy

FUJI’s CP-643E belongs to the CP-6 series of chip shooters, combining stability, speed, and flexibility. It supports up to 140 feeder positions (8 mm tape), a maximum PCB size of 457 × 356 mm, and components up to 6 mm in height. The dual PCB loading system enables efficient continuous operation, reducing downtime and improving throughput. Robust design, simple maintenance, and reliable operation make it a preferred choice for SMT assembly lines requiring both speed and accuracy.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product parameters

| Item | Specification |

|---|---|

| Model | FUJI CP-643E |

| Series | FUJI CP-6 Series |

| Placement Speed | Max. 40,000 CPH |

| Placement Accuracy | ±0.01 mm (3σ) |

| Component Range | Chip, resistor, capacitor, small ICs |

| Max PCB Size | 457 × 356 mm |

| Min PCB Size | 80 × 60 mm |

| PCB Thickness | 0.3 – 4.0 mm |

| Max Component Height | 6 mm |

Product Display

微信图片_20180710163420

微信图片_20180710163505

微信图片_20180710163513

Efficiency Elevated with Precision

Feeder Capacity Up to 140 feeders (8 mm tape) Mount Head Multi-head configuration (20 heads typical) Vision System Optical recognition with auto alignment Drive System Servo motor + precision linear guide Power Supply 3 Phase, 200–480V AC, 10 kVA Air Supply 0.5 MPa ±10% Machine Dimensions 4843 × 1734 × 1851 mm Weight Approx. 6,500 kg Noise Level ≤ 75 dB Operating Temperature 15 – 35°C Manufacturer FUJI Corporation, Japan

| Feeder Capacity | Up to 140 feeders (8 mm tape) |

| Mount Head | Multi-head configuration (20 heads typical) |

| Vision System | Optical recognition with auto alignment |

| Drive System | Servo motor + precision linear guide |

| Power Supply | 3 Phase, 200–480V AC, 10 kVA |

| Air Supply | 0.5 MPa ±10% |

| Machine Dimensions | 4843 × 1734 × 1851 mm |

| Weight | Approx. 6,500 kg |

| Noise Level | ≤ 75 dB |

| Operating Temperature | 15 – 35°C |

| Manufacturer | FUJI Corporation, Japan |

FAQ

1

What types of components can this machine handle?

It can handle a wide range of SMT components, from small passive components like 0201 to larger ICs and connectors, providing flexibility for various production needs.

2

How accurate is the placement process?

The machine offers high-precision placement, typically within ±50 μm, ensuring reliable assembly for complex PCBs.

3

What PCB sizes are supported?

It supports various PCB sizes, from small boards to medium panels, allowing for versatile manufacturing applications.

4

How can I maintain the machine for optimal performance?

Regular maintenance, including cleaning nozzles, checking feeders, and lubricating moving parts, helps ensure stable operation and reduces downtime.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Ready to work with us ?

Find us here:

Useful Links

Products

Contact Us

Contact person: jiaqin luo

Tel / WhatsApp: +86 13926805686

E-mail: aismtsupplier@gmail.com

Add:

Songshan Lake Industrial Building, Dongguan, Guangdong, China zip 523808