Yamaha Smt Feeder Klj-Mc200-000 – Zs Series 12mm Automatic Tape Feeder For Ys/Ysm Placement Machines

The Yamaha SMT ZS 12mm Feeder (KLJ-MC200-000) is a high-efficiency electronic tape feeder engineered for Yamaha YS and YSM series pick-and-place machines. Designed for precise delivery of 12mm tape components, it integrates a motorized ZS feeding system that ensures accurate, stable, and vibration-free operation. This feeder supports a wide range of SMD parts—including resistors, capacitors, and ICs—making it ideal for high-speed, high-volume SMT production environments.

With a plug-and-play structure, the KLJ-MC200-000 allows for rapid installation and changeovers, reducing downtime and enhancing line flexibility. Its durable construction ensures long-term reliability with minimal maintenance, while intelligent sensor feedback guarantees smooth tape advancement and accurate pickup synchronization.

Key benefits include improved placement accuracy, enhanced productivity, lower operating costs, and compatibility with Yamaha’s advanced automation systems. Whether you're scaling production or optimizing an existing line, this 12mm ZS feeder delivers the speed, precision, and dependability that modern electronics manufacturing demands.

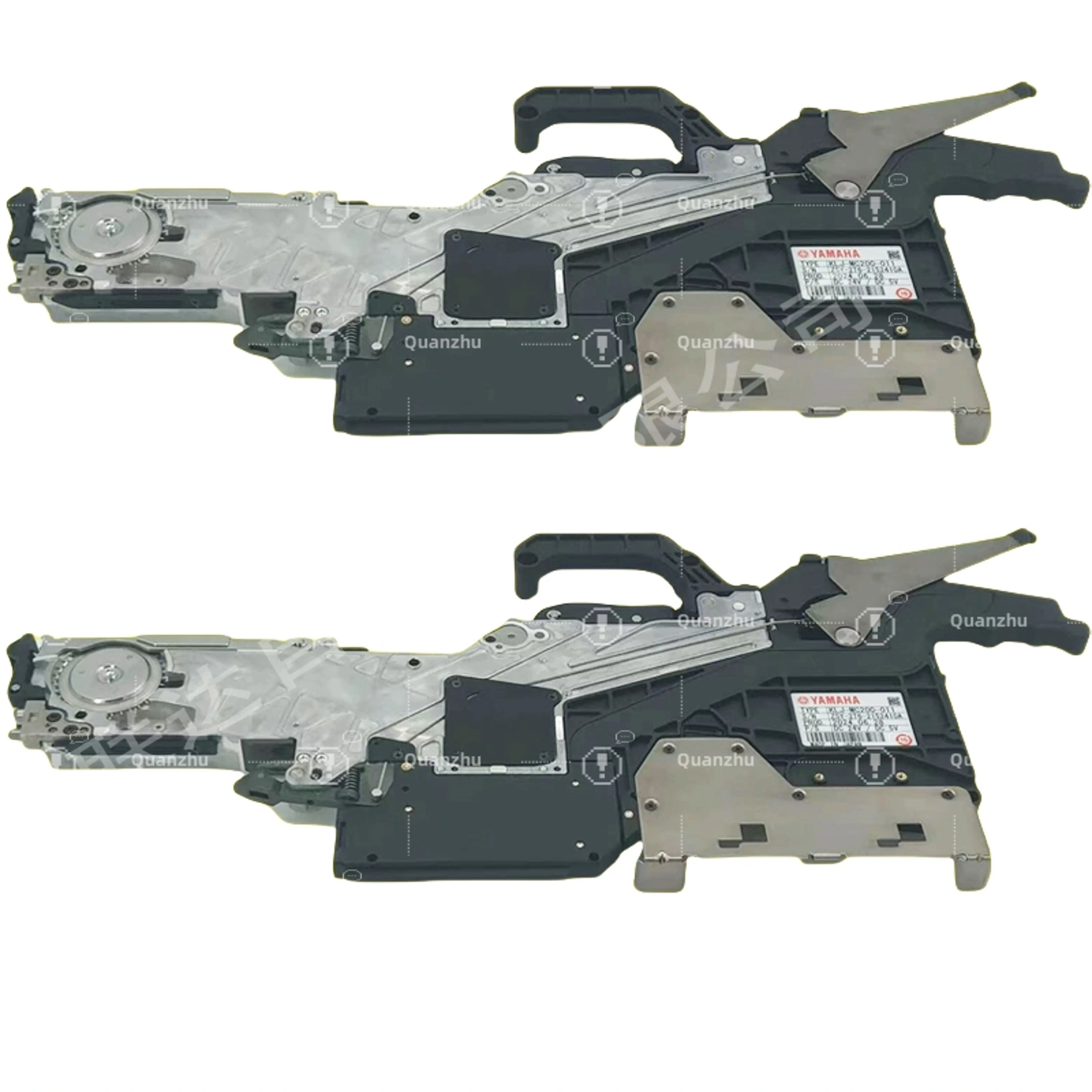

Product Introduction

The Yamaha SMT Feeder KLJ-MC200-000 is a high-precision 12mm tape feeder from the ZS Series, engineered for use with Yamaha YS and YSM pick-and-place machines. Designed for smooth, accurate, and high-speed component feeding, this feeder ensures stable operation even under intensive SMT production demands. Its motorized system enhances feeding consistency, while the quick-installation design allows for easy line changeovers. Ideal for delivering medium-sized components such as resistors, capacitors, and ICs, it improves placement accuracy, reduces downtime, and supports long-term production efficiency. Built with Yamaha’s trusted quality and reliability, this feeder is a valuable solution for electronics manufacturers seeking to optimize assembly line performance.

Product Display

Product Advantages

Application Scenario

FAQ