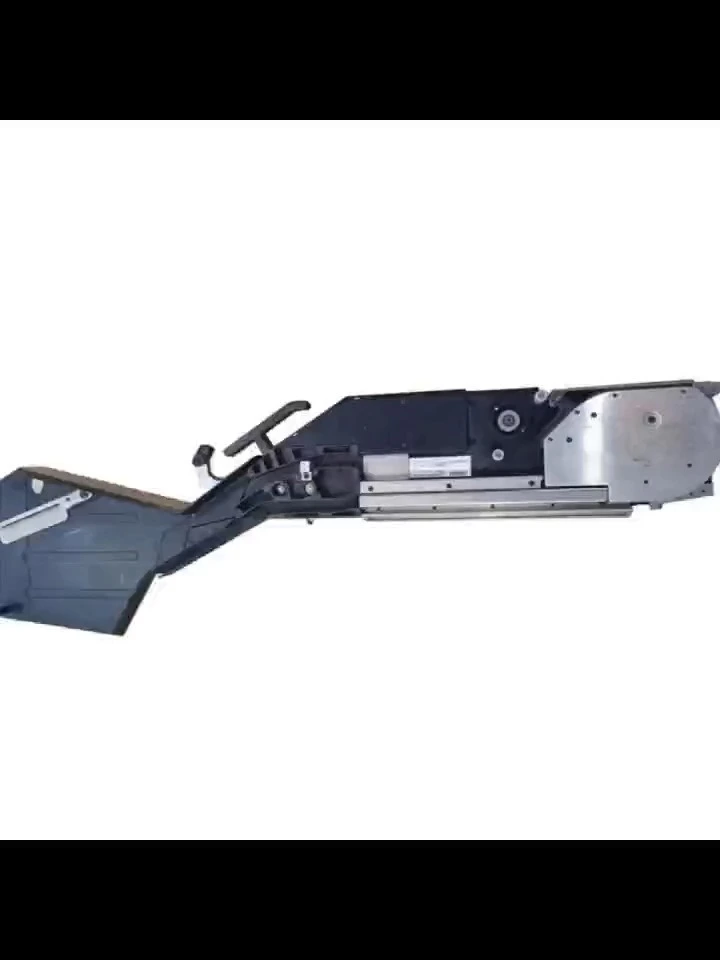

Universal 8MM/12MM/16MM/24MM Electric SMT Feeders | High-Speed Durable Feeder for Pick & Place Machines

Product Introduction

The Universal chip mounter electric feeder is compatible with the entire range of 8MM - 72MM tape. It is driven by a high - precision stepper motor and equipped with intelligent anti - jam sensing technology. The feeding speed reaches 0.1 seconds per piece, and it is suitable for components from 0402 to SMD IC. The fuselage is integrally formed with aviation aluminum, which is impact - resistant and corrosion - resistant. The continuous operation life exceeds 5 million times, and it supports high - intensity production for 7×24 hours. It has a built - in self - inspection and deviation - correction system that can monitor the position of the tape in real - time. The material throwing rate is less than 0.03%, which significantly improves the SMT mounting yield. It has passed CE/FCC certifications and is suitable for precision applications such as automotive electronics, LED lighting, and 5G modules.

Product Display

Product Advantages

Application Scenario

FAQ