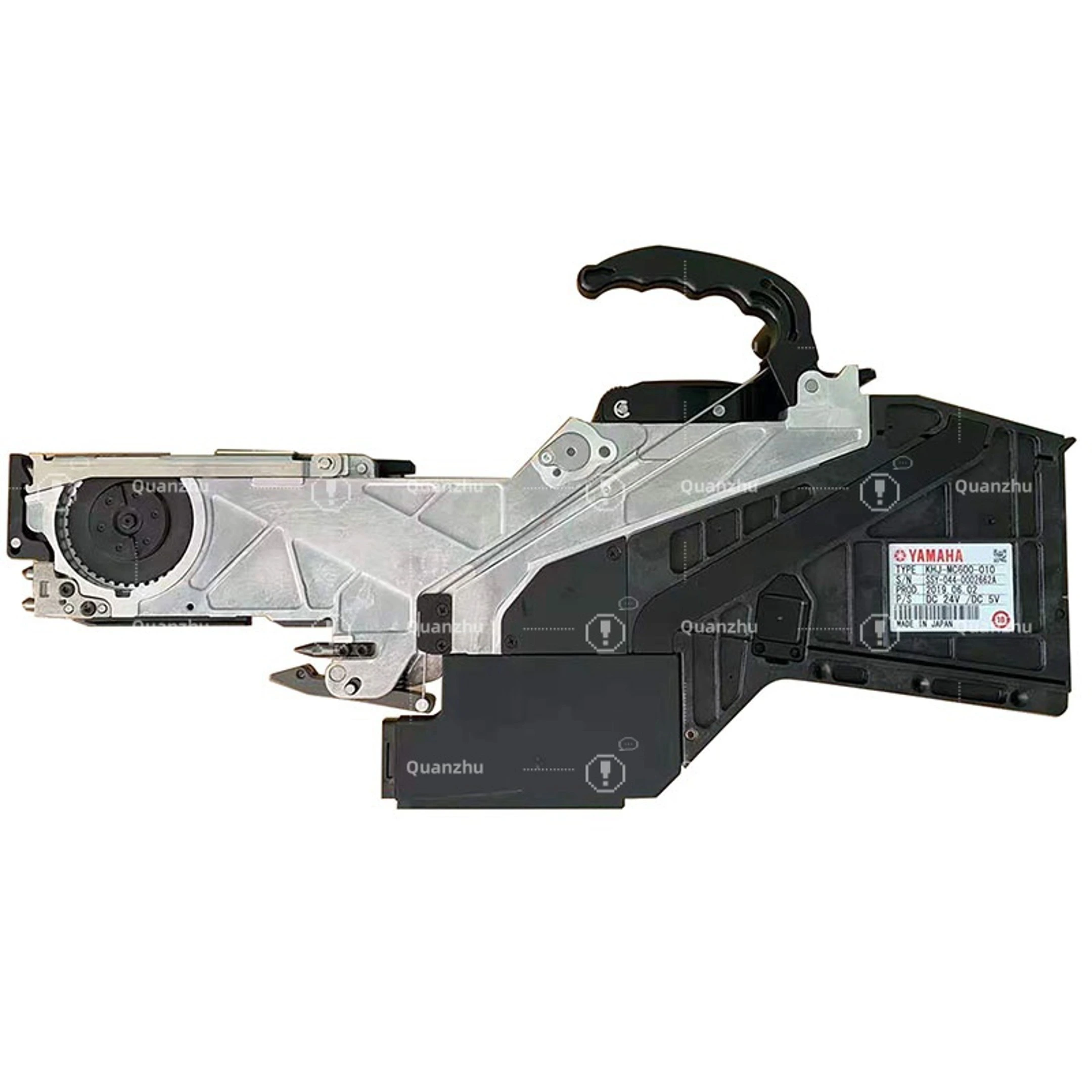

Smt Yamaha Feeder Ss 44mm Khj-Mc600-000 For Pick And Place Machine

SMT Yamaha Feeder SS 44mm KHJ-MC600-000 – Precision Feeding for Maximum Efficiency

Key Features:

-

Model: KHJ-MC600-000

-

Feeder Width: 44mm

-

Compatibility: Designed for Yamaha SMT machines (YV, YG, YS series)

-

Type: Original standard stainless steel feeder

Product Overview:

The SMT Yamaha Feeder SS 44mm KHJ-MC600-000 is engineered for high-speed, high-precision component feeding in modern SMT production lines. Tailored specifically for Yamaha pick-and-place machines, it guarantees smooth and reliable operation even under continuous use.

Functional Highlights:

-

Accurate Feeding: Ensures components are delivered precisely to the mounting head, reducing placement errors.

-

Durable Build: Made with industrial-grade materials for long-term use and resistance to wear and tear.

-

Modular Design: Enables quick installation and simple maintenance, minimizing downtime.

-

Stable Operation: Advanced mechanical structure minimizes jamming and misfeeds.

Advantages:

-

Increased Production Efficiency: With fewer errors and stoppages, your line keeps moving at optimal speed.

-

Reduced Maintenance Costs: Durable construction leads to fewer replacements and service interruptions.

-

Broad Compatibility: Supports multiple Yamaha machine models, adding flexibility to your production setup.

-

Time-Saving Design: Tool-less feeder changeover saves valuable production time.

Customer Value:

-

Boost Productivity: Achieve faster throughput without sacrificing accuracy.

-

Maximize ROI: High reliability means fewer delays and long-term savings.

-

Trusted Performance: Used by industry professionals worldwide for its consistent quality and performance.

Product Introduction

The SMT Yamaha Feeder SS 44mm KHJ-MC600-000 is a high-precision feeder specially designed for Yamaha surface mount technology (SMT) equipment, suitable for 44mm wide tape. This model features stable feeding performance and excellent durability, effectively enhancing the efficiency and reliability of the pick-and-place production line. Its modular design allows for easy installation and maintenance, and it is widely compatible with various Yamaha pick-and-place machine models, such as the YV, YG, and YS series.

Product Display

Product Advantages

Application Scenario

FAQ