SMT JUKI Feeder FS44MM – 44mm Deep Pocket Tape Feeder for JUKI SMT Placement Machines

Constructed with durable materials and a reinforced deep pocket design, the JUKI FS44MM feeder is optimized for handling 44mm wide carrier tapes. Its deep pocket structure stabilizes large or top-heavy components during high-speed operation, minimizing misalignment, shifting, and jamming. Fully compatible with JUKI KE, RS, and FX series pick-and-place machines, the FS44MM supports quick changeovers and easy maintenance. It is widely used in automotive electronics, telecom systems, industrial automation, and power electronics manufacturing—making it an essential tool for high-accuracy SMT assembly involving large components.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Introduction

Constructed with durable materials and a reinforced deep pocket design, the JUKI FS44MM feeder is optimized for handling 44mm wide carrier tapes. Its deep pocket structure stabilizes large or top-heavy components during high-speed operation, minimizing misalignment, shifting, and jamming. Fully compatible with JUKI KE, RS, and FX series pick-and-place machines, the FS44MM supports quick changeovers and easy maintenance. It is widely used in automotive electronics, telecom systems, industrial automation, and power electronics manufacturing—making it an essential tool for high-accuracy SMT assembly involving large components.

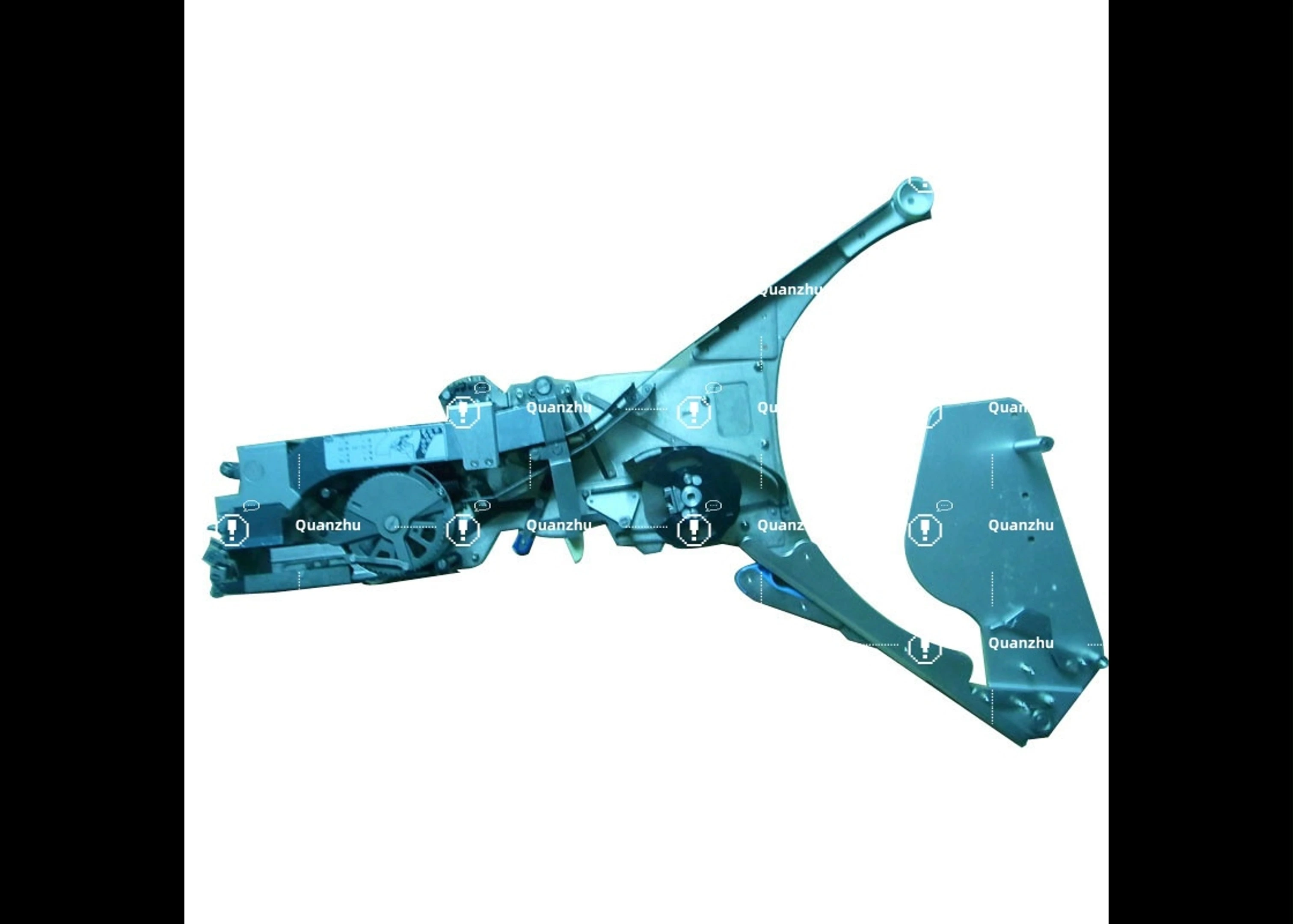

Product Display

1 (216)

1 (215)

0 (150)

微信图片_20241010174838

微信图片_20241010174911

微信图片_20241010174916

微信图片_20241010174927

微信图片_20241010174932

微信图片_20241010174937

Product Advantages

High Feeding Accuracy Precision mechanical design ensures smooth and accurate component feeding, significantly improving placement accuracy.

Excellent Durability Built with high-strength, wear-resistant materials, the feeder supports long-term continuous operation with reduced maintenance costs.

Great Compatibility Fully compatible with Fuji CP6 series pick and place machines. Easy to install and operate without complex adjustments.

Enhanced Production Efficiency Stable feeding performance minimizes jamming and missing components, ensuring higher machine uptime and improved production efficiency.

Application Scenario

Consumer electronics

Smartphone motherboards, TWS earphone circuit boards, smartwatch modules

Automotive electronics

ECU control board, vehicle-mounted sensors, charging modules for new energy vehicles

LED display

Mini LED backlight module, outdoor display screen unit

Medical electronics

PCBs for medical imaging equipment, implantable sensors

FAQ

1

What is the typical lifespan of an SMT Feeder? How to extend its service life?

Standard lifespan: The average lifespan of an industrial-grade SMT Feeder is 3 to 5 million cycles. For example, the Yamaha CL series can reach up to 8 million cycles.

2

How to fix communication errors between SMT Feeder and pick-and-place machine?

Confirm that the PIN pins of the Feeder interface are not bent or oxidized. Check whether the Feeder firmware version supports the model of the chip mounter. Restart the control unit of the chip mounter and reload the parameter configuration file of the Feeder.

3

Can third-party SMT Feeders match OEM performance?

Third-party Feeders have an advantage in terms of short-term costs, but there are significant differences. For high-precision and large-batch production, it is preferable to choose the original factory feeders. For trial production or scenarios with low complexity, it is possible to try high-quality third-party brands.

4

How to quickly replace worn parts like feeder gears?

Cut off the power supply and remove the tape.

Use a 3mm hexagonal wrench to remove the gear cover plate (pay attention to the spring tension).

Take out the old gear set and compare the pitch consistency with that of the new gear.

Apply thermal conductive silicone grease and then install the new gear.

Use a calibration jig to test the feeding tension (target value: 2.5N±0.3N).

5

Can you customize SMT Feeders for non-standard tape widths?

YES

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Ready to work with us ?

Find us here:

Useful Links

Products

Contact Us

Contact person: jiaqin luo

Tel / WhatsApp: +86 13926805686

E-mail: aismtsupplier@gmail.com

Add:

Songshan Lake Industrial Building, Dongguan, Guangdong, China zip 523808