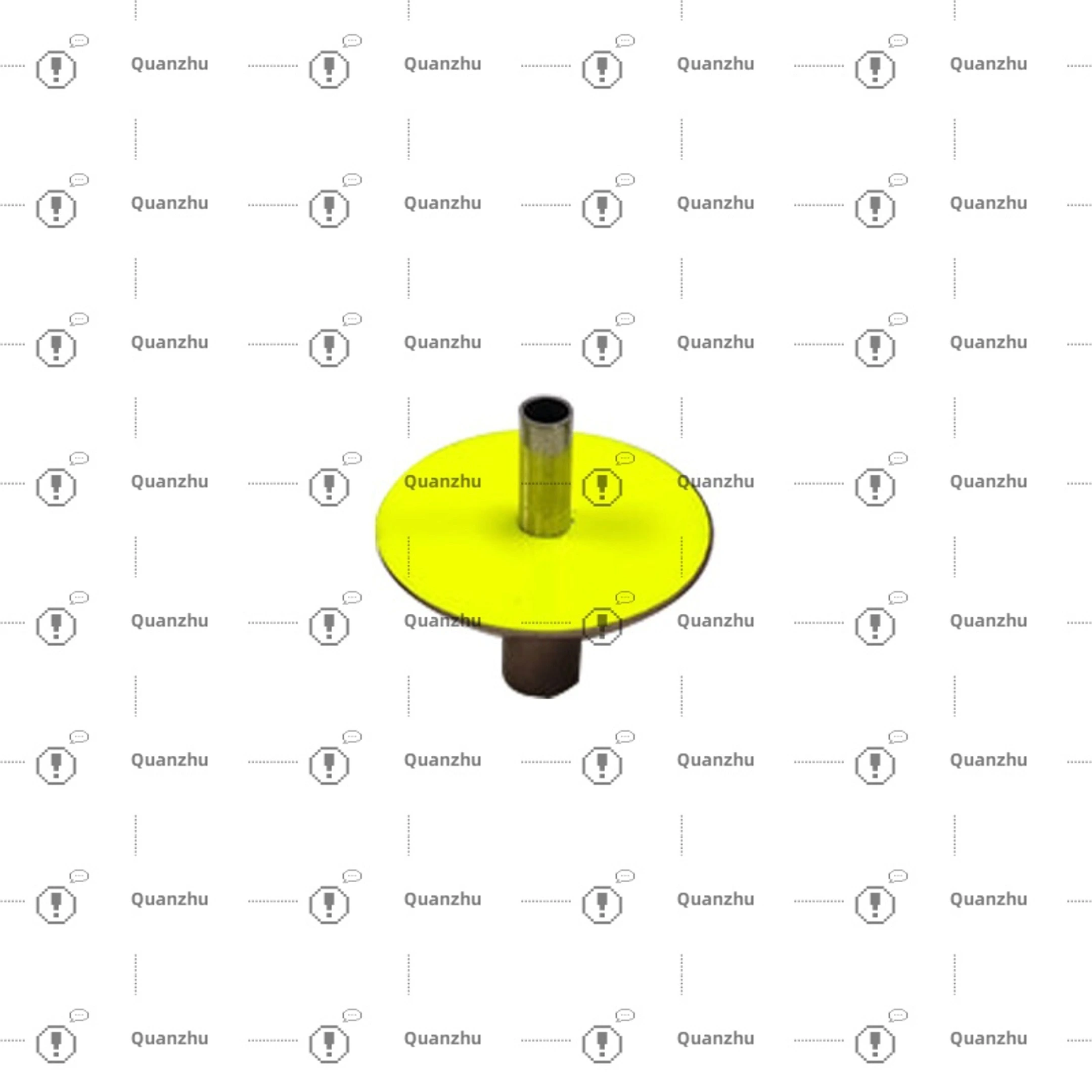

SMT FUJI Nozzle CP7 2.5 ADCPH956 – Durable High-Precision Nozzle for FUJI CP7 Machines

The FUJI CP7 2.5 Nozzle (ADCPH956) is a precision-engineered SMT placement nozzle designed for FUJI CP7 series machines. Constructed from durable, wear-resistant materials, it ensures long-lasting performance and consistent suction stability in demanding manufacturing environments. Optimized for medium to large component placement, this nozzle features an advanced airflow design that improves suction efficiency and reduces misplacement rates, thereby enhancing overall production yield. Essential for high-speed, automated SMT assembly lines, the ADCPH956 nozzle delivers reliable and accurate mounting performance.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Introduction

The FUJI CP7 2.5 Nozzle (Model: ADCPH956) is specifically designed for FUJI CP7 series pick-and-place machines, ideal for high-precision placement of medium to large electronic components. Manufactured from high-strength, wear-resistant materials, this nozzle maintains stable suction force and accuracy even after prolonged use. Its optimized airflow channel enhances suction efficiency, effectively reducing placement errors and improving production yield. As a crucial component of SMT production lines, the ADCPH956 nozzle provides reliable support for automated assembly processes.

Product Display

20211123162633308

20211123162643207

20211123162638628

5 (16)

2 (52)

主图_3_proc (2)

主图_1_proc (3)

O1CN014TXZB31zRggl6nN8q_!!2210322836711

主图_5_proc (3)

Product Advantages

High Precision Placement Ensures accurate mounting of 0.7mm and smaller components, reducing placement errors in high-density PCBs.

Optimized for FUJI CP6 Machines Fully compatible with FUJI CP6 series, ensuring seamless integration and stable performance in high-speed production environments.

Durable & Wear-Resistant Material Built from high-quality materials to withstand continuous use, extending the nozzle’s service life and reducing maintenance frequency.

Application Scenario

Consumer electronics

Smartphone motherboards, TWS earphone circuit boards, smartwatch modules

Automotive electronics

ECU control board, vehicle-mounted sensors, charging modules for new energy vehicles

LED display

Mini LED backlight module, outdoor display screen unit

Medical electronics

PCBs for medical imaging equipment, implantable sensors

FAQ

1

What are SMT nozzles and what are they used for?

SMT nozzle, pick and place nozzle, surface mount technology, component placement, vacuum nozzle

2

How do I choose the right SMT nozzle for my components?

SMT nozzle selection, nozzle size, component size, nozzle material, nozzle type, pitch size, pick and place machine

3

How often should I replace or clean my SMT nozzles?

SMT nozzle cleaning, nozzle replacement, nozzle maintenance, nozzle lifespan, contamination, pick and place errors

4

How to quickly replace worn parts like feeder gears?

Cut off the power supply and remove the tape.

Use a 3mm hexagonal wrench to remove the gear cover plate (pay attention to the spring tension).

Take out the old gear set and compare the pitch consistency with that of the new gear.

Apply thermal conductive silicone grease and then install the new gear.

5

Where can I buy SMT nozzles (new or used) for my pick and place machine?

buy SMT nozzles, SMT nozzle supplier, SMT nozzle distributor, used SMT nozzles, SMT nozzle price, SMT nozzle online store, pick and place nozzle vendor.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Ready to work with us ?

Find us here:

Useful Links

Products

Contact Us

Contact person: jiaqin luo

Tel / WhatsApp: +86 13926805686

E-mail: aismtsupplier@gmail.com

Add:

Songshan Lake Industrial Building, Dongguan, Guangdong, China zip 523808