SMT Feeder 8×4mm Compatible with Samsung CP Series – Reliable Tape Feeding for Micro Components

The Samsung SMT CP Series 8×4mm Feeder is a compact, high-precision component feeding solution engineered to support high-speed, high-volume SMT production environments. Designed specifically for compatibility with Samsung CP series pick-and-place machines—including CP40, CP45, and CP60 models—this feeder supports 8mm-wide carrier tapes with a 4mm pitch, which is the industry-standard format for feeding small and lightweight surface-mount devices (SMDs).

Optimized for components such as chip resistors, ceramic capacitors, diodes, and small transistors, the 8×4mm feeder ensures highly accurate tape indexing and stable component presentation at the nozzle pick-up point. Its precision-driven feeding mechanism minimizes misfeeds, improves placement accuracy, and helps maintain consistent production quality even at high operational speeds.

The feeder's rugged construction ensures long-term durability under continuous use, while its plug-and-play installation design allows for fast line changeovers and minimal downtime. Supporting both paper and embossed plastic carrier tapes, it provides exceptional flexibility for different packaging types and production needs.

Product Introduction

The Samsung SMT CP Series 8×4mm Feeder is a high-precision tape feeder specifically designed for efficient handling of small SMD components in high-speed automated assembly environments. Tailored for Samsung CP series pick-and-place machines, this feeder supports 8mm-wide carrier tapes with a 4mm pitch—ideal for resistors, capacitors, diodes, and other miniature components.

Engineered for stable performance, it features accurate tape indexing and smooth component advancement to ensure precise placement and minimize component loss. Its durable structure and easy plug-and-play installation reduce maintenance efforts and enhance production uptime, making it a vital solution for electronics manufacturers focused on productivity and placement quality.

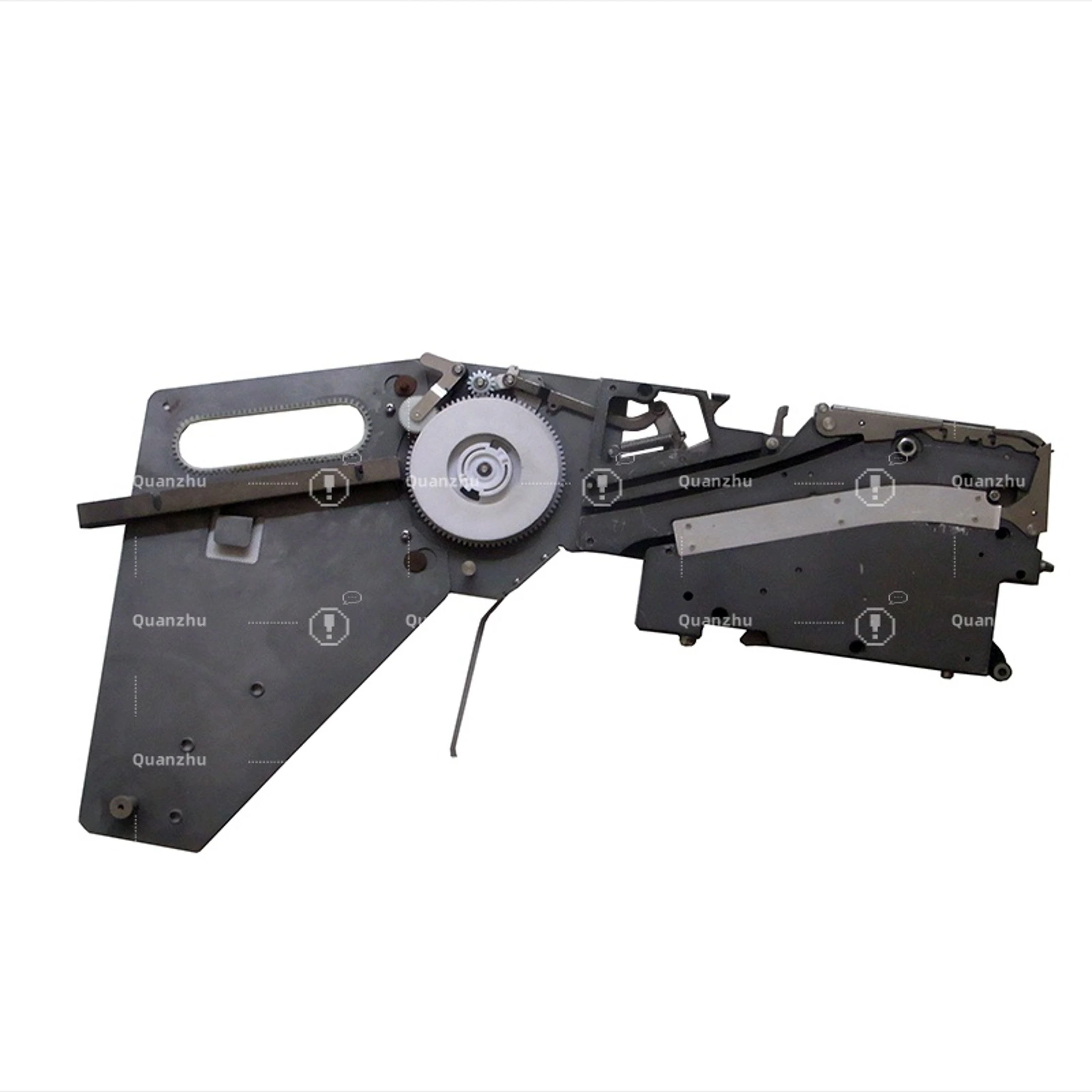

Product Display

Product Advantages

Application Scenario

FAQ