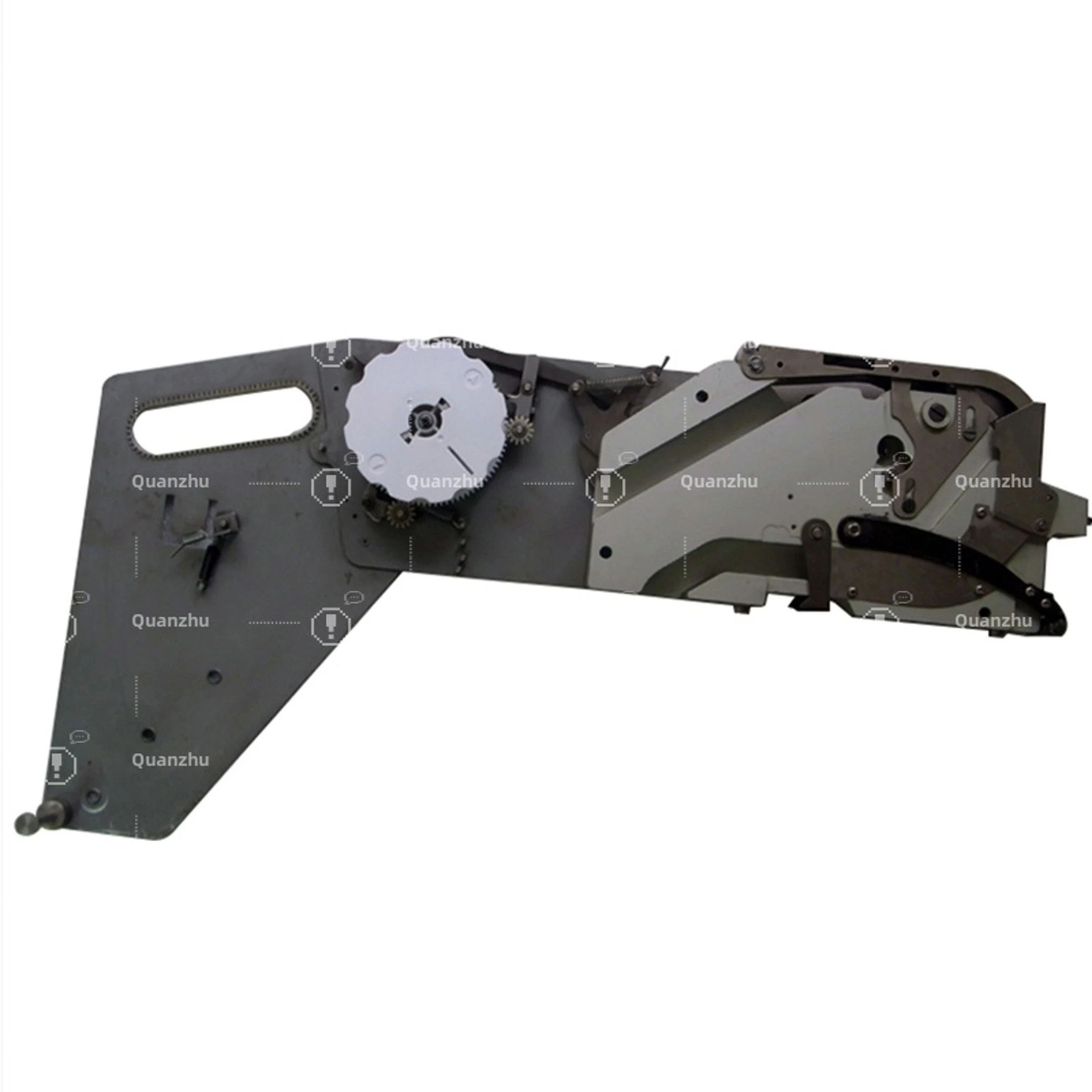

Samsung SMT CP Series 24mm Feeder – High-Precision Tape Feeding Solution for Pick-and-Place Systems

The Samsung SMT CP Series 16mm Feeder is a high-precision, industrial-grade solution designed to deliver reliable component feeding in modern surface mount technology (SMT) environments. Specifically engineered for compatibility with Samsung CP series pick-and-place machines, this 16mm feeder ensures smooth, accurate tape advancement for mid-sized electronic components. Its durable mechanical design, combined with a stable stepper motor drive system, minimizes feeding errors and reduces maintenance needs during long production runs.

With a plug-and-play interface, the feeder supports rapid changeovers and seamless integration into high-mix, high-speed SMT assembly lines. It accommodates a wide range of standard 16mm carrier tapes, including both paper and plastic types, making it a versatile choice for electronics manufacturers seeking enhanced throughput and production stability.

Application Industries:

The CP Series 16mm Feeder is widely used in consumer electronics, automotive electronics, telecommunications, industrial control systems, and medical device manufacturing. Its precision and efficiency make it ideal for high-reliability applications where accuracy and speed are critical to product performance and production yield.

Whether in small-batch prototyping or high-volume manufacturing, the CP 16mm feeder offers exceptional precision, repeatability, and operational efficiency.

Product Introduction

The Samsung SMT CP Series 16mm Feeder is a precision-engineered tape feeding solution designed specifically for Samsung CP pick-and-place machines. Optimized for 16mm component tapes, it delivers stable, accurate, and high-speed feeding performance, ensuring reliable component placement during SMT production. Built with industrial-grade materials and a robust drive mechanism, this feeder supports continuous operation in demanding manufacturing environments. Its plug-and-play design allows for fast setup and quick reel changes, reducing downtime and improving production efficiency. Ideal for medium to large-scale electronics assembly lines, it enhances throughput, minimizes error rates, and supports a wide range of component packaging formats.

Product Display

Product Advantages

Application Scenario

FAQ