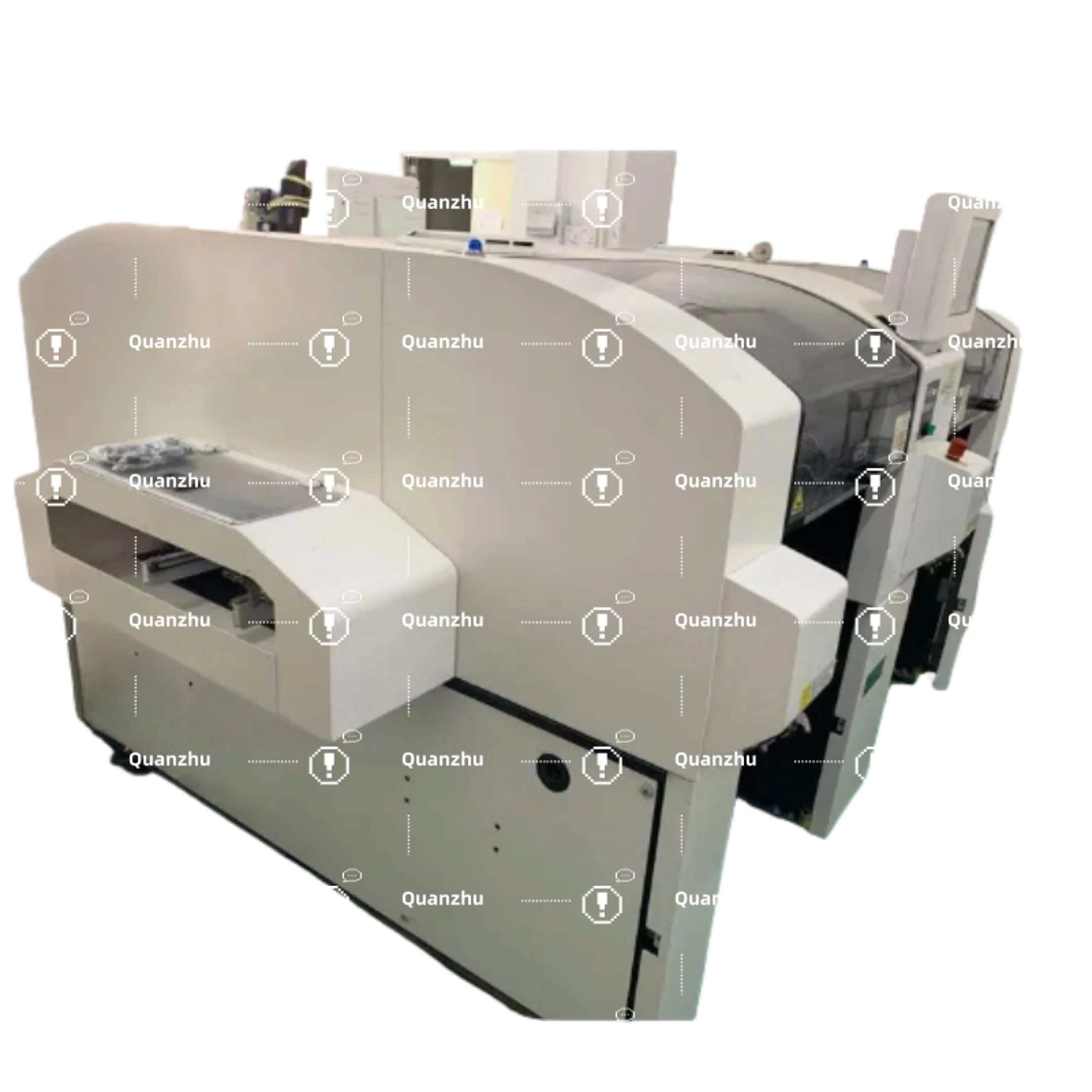

Panasonic CM202 SMT Pick and Place Machine | High-Speed Automatic Chip Mounter for LED & PCB Assembly

High precision Panasonic CM202 SMT machine for efficient LED and PCB production

-

High-Speed Placement – Up to 45,000 CPH for efficient SMT production.

-

High Precision – ±0.05mm placement accuracy ensures stable component quality.

-

LED & PCB Compatibility – Ideal for lighting module and circuit board assembly.

-

Flexible Setup – Supports wide range of components from 0201 to 32mm devices.

-

Intelligent Feeder Control – Ensures smooth and accurate part feeding.

-

Proven Reliability – Panasonic’s robust design for continuous 24/7 operation.

-

Cost-Effective Solution – Reduces downtime and improves production yield.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product parameters

| Item | Specification |

|---|---|

| Model | Panasonic CM202 |

| Type | High-Speed SMT Pick and Place Machine |

| Placement Speed | Up to 45,000 CPH (components per hour) |

| Placement Accuracy | ±0.05mm (Chip) |

| Applicable Components | 0201 to 32mm QFP/BGA/SOP |

| PCB Size | Max 510mm × 460mm |

| PCB Thickness | 0.4mm – 4.0mm |

Product Display

wechat_2025-10-10_154652_810

wechat_2025-10-10_154527_120

wechat_2025-10-10_154641_121

Efficiency Elevated with Precision

| Component Height | Up to 18mm |

| Feeder Capacity | Up to 120 slots (8mm tape) |

| Power Supply | AC 200–220V, 3 Phase, 50/60Hz |

| Dimensions (L×W×H) | 1,700mm × 1,650mm × 1,500mm |

| Machine Weight | Approx. 1,900 kg |

| Origin | Japan |

| Condition | 100% Tested, Fully Operational |

FAQ

1

What types of components can this machine handle?

It can handle a wide range of SMT components, from small passive components like 0201 to larger ICs and connectors, providing flexibility for various production needs.

2

How accurate is the placement process?

The machine offers high-precision placement, typically within ±50 μm, ensuring reliable assembly for complex PCBs.

3

What PCB sizes are supported?

It supports various PCB sizes, from small boards to medium panels, allowing for versatile manufacturing applications.

4

How can I maintain the machine for optimal performance?

Regular maintenance, including cleaning nozzles, checking feeders, and lubricating moving parts, helps ensure stable operation and reduces downtime.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Ready to work with us ?

Find us here:

Useful Links

Products

Contact Us

Contact person: jiaqin luo

Tel / WhatsApp: +86 13926805686

E-mail: aismtsupplier@gmail.com

Add:

Songshan Lake Industrial Building, Dongguan, Guangdong, China zip 523808